Steeligent – Your Partner for Sustainable Steel Procurement and Intelligent Supply Solutions

From Mines to Steel

The journey from raw material extraction to the finished steel product is a precisely coordinated process that requires deep expertise and advanced technologies. It all begins in the mines, where iron ore, the heart of steel production, is carefully extracted. This ore is refined in state-of-the-art facilities and converted into pig iron, which is then melted and alloyed in steelworks to achieve the desired properties.

Every step requires close collaboration between experts, engineers, and logistics personnel to ensure that quality, sustainability, and efficiency are in harmony. From mining to processing to the delivery of finished steel products, our goal is to supply industrial production with first-class materials – precisely, sustainably, and reliably. From mines to steel: We set standards in steel supply and production support.

Green Steel for a Sustainable Future

Green steel is the answer to the challenges of our time – it combines the strength and versatility of conventional steel with a clear focus on environmental protection and sustainability. Through the use of renewable energies, the minimization of CO₂ emissions, and innovative manufacturing processes, green steel actively contributes to reducing the ecological footprint. By choosing green steel, you not only support environmentally friendly production but also a more sustainable future for the industry. Together we can drive the shift towards environmentally conscious solutions – economically strong, ecologically responsible.

Find Out More

Green Steel for the Future

Green steel represents a revolution in the steel industry. Instead of conventional processes that release large amounts of CO₂, green steel relies on innovative technologies such as hydrogen-based production or the use of renewable energies. These processes significantly reduce the ecological footprint and create a new standard for responsible industrial production.

How Green Steel Protects the Environment

The production of green steel minimizes greenhouse gas emissions and conserves natural resources. Through the use of recycled materials and clean energy sources, the production process is made more efficient and environmentally friendly. This contributes to the reduction of global emissions while offering the same high-quality as traditionally produced steel.

Your Contribution to a Sustainable Industry

By choosing green steel, you not only promote sustainable solutions but also a future-oriented economy. Companies that rely on environmentally friendly alternatives benefit from a positive image, stronger customer loyalty, and a pioneering role in the area of ecological responsibility. Together, we can build an emissions-free industry and protect the world for future generations.

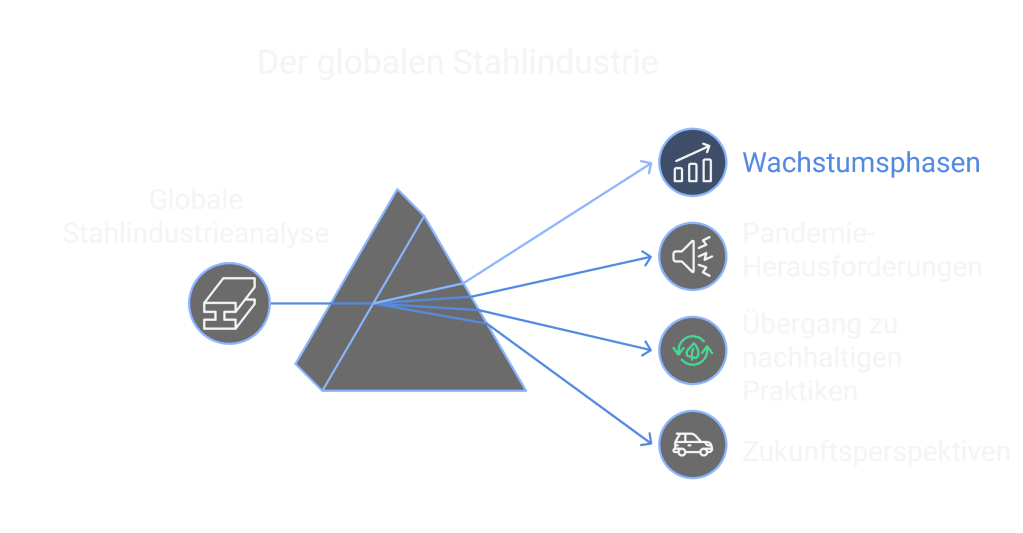

Global Developments for Steel and Steel Production (2011-2025)

2011–2020

Building and Adaptation

In the early 2010s, the steel industry experienced growth driven primarily by China, which accounted for up to 50% of global steel production. The focus was on infrastructure investments and urbanization. At the same time, increased regulation of CO₂ emissions in Europe and North America led to innovations in production, including the introduction of more energy-efficient processes and the development of recycling methods for scrap steel.

2021–2023

Pandemic and Recovery

The COVID-19 pandemic brought major disruptions to steel production and demand in 2020/21. However, the market recovered rapidly in 2022, supported by government stimulus programs, particularly in the infrastructure sector. At the same time, the trend towards ‚green steel‘ continued, driven by strict climate targets and consumer demand for sustainable materials. Countries like India and regions like Africa began to emerge as new growth markets.

2024 – 2025

Sustainability and Innovation

Towards the end of 2024, the steel industry faces challenges such as fluctuating demand, geopolitical tensions, and increased production costs in traditional markets. At the same time, the potential in emerging regions such as India and Southeast Asia is growing, driven by investments in infrastructure and industry. The focus is increasingly on low-emission technologies such as hydrogen-based processes to achieve global climate goals.

Low-emission technologies, particularly hydrogen-based processes, are becoming increasingly important to achieve global climate targets. The growing demand for steel for renewable energies, electric vehicles, and sustainable construction projects marks the beginning of a long-term realignment towards a more environmentally friendly and sustainable industry.

Our Products for the Steel and Raw Materials Industry

We offer a wide range of mineral raw materials and steel products specifically designed to meet the needs of the steel and metal industries. Our high-quality materials support the production, processing, and refinement of steel and other metals.

Products for Steel Production

Iron Ore Concentrate – High-Quality Raw Material for Steel Production

Learn More

Iron ore concentrate is a critical raw material for the steel industry. Our high-quality concentrate is produced using state-of-the-art processing techniques and is distinguished by its high purity, making it ideal for further processing in blast furnaces or direct reduction plants.

Technical Specifications

- Purity: Fe content ≥ 67%

- Particle Size: 0-10 mm

- Moisture Content: ≤ 9%

- Impurities: Low sulfur and phosphorus content

Applications

- Steel Mills: Ideal for producing pig iron and steel in blast furnaces.

- Direct Reduction: Perfect for sponge iron (DRI) production.

- Construction Industry: Used as a base for steel-based construction materials.

Product Advantages

- Premium Quality: Ensures maximum efficiency in production processes.

- Environmentally Friendly: Processing methods reduce emissions.

- Reliable Supply: Supported by dependable logistics chains.

Why Choose Us?

- Extensive Experience: Years of expertise in raw material supply.

- Customizable Specifications: Tailored to meet your specific requirements.

- Expert Support: Assistance from order placement to delivery.

Contact us for a non-binding quote or more information about iron ore concentrate. Our team is always available to assist you.

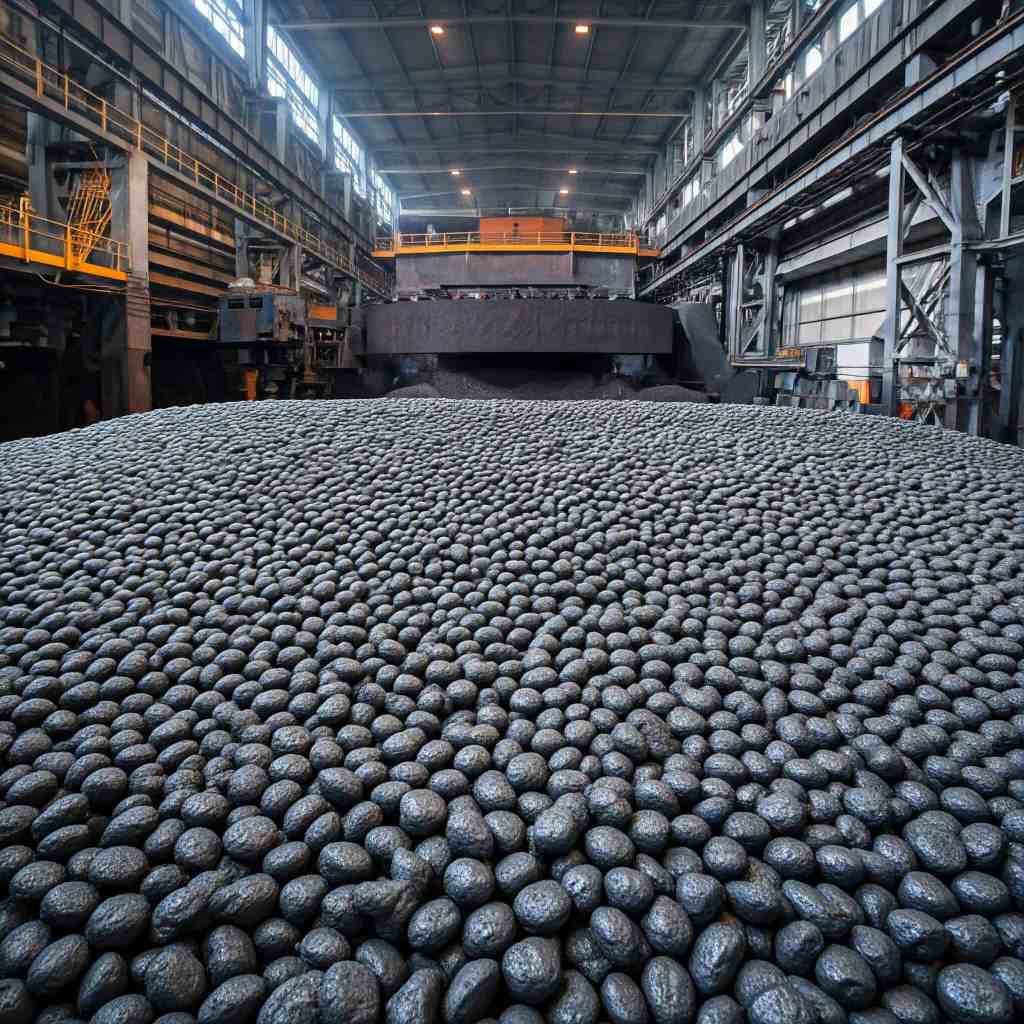

Iron Ore Pellets – Efficient Raw Material for Modern Steel Production

Learn More

Iron ore pellets are a refined raw material for producing pig iron and steel. Their spherical shape and uniform size provide an ideal foundation for efficient processes in blast furnaces and direct reduction plants. Made from high-quality iron ore concentrates, our pellets are renowned for their superior quality.

Technical Specifications

- Purity: Fe content ≥ 65%

- Particle Size: Standard size 8-16 mm

- Moisture Content: ≤ 8%

- Tensile Strength: ≥ 250 kg/pellet

- Impurities: Low sulfur and phosphorus content

Applications

- Blast Furnaces: Ideal for pig iron reduction with minimal slag formation.

- Direct Reduction Plants (DRI): Effective for sponge iron production.

- Steel Production: A foundation for manufacturing high-quality steel.

Product Advantages

- Efficient Processes: The spherical shape and homogeneous size ensure uniform air circulation and rapid reduction.

- Higher Energy Efficiency: Reduced energy consumption during processing.

- Lower Environmental Impact: Sustainable production with minimal waste.

- Stable Quality: Consistent chemical composition and mechanical strength.

Why Choose Our Iron Ore Pellets?

- Premium Raw Materials: Only the best iron ore is used to ensure optimal results.

- State-of-the-Art Production: Manufactured using eco-friendly technologies for maximum efficiency.

- Tailored Solutions: Pellet specifications customized to meet customer requirements.

- Reliable Delivery: Flexible logistics solutions for on-time global shipments.

Contact Us

Have questions or need a customized quote for iron ore pellets? Contact our team for more information. We’ll help you find the best solutions for your needs.

Sponge Iron – Efficient Precursor for Steel Production

Learn More

Sponge Iron, also known as Direct Reduced Iron (DRI), is a high-quality raw material for steel manufacturing. It is produced by reducing iron ore at low temperatures without melting, resulting in excellent purity and an ideal structure, specifically suited for use in Electric Arc Furnaces (EAF) and Induction Furnaces.

Technical Specifications

- Purity: Fe content ≥ 90%

- Density: 1.6 – 2.0 g/cm³

- Carbon Content: 0.1 – 0.3%

- Impurities: Very low sulfur and phosphorus content

- Form: Granules or lumps

Applications

- Electric Arc Furnaces (EAF): Sponge Iron is an energy-efficient alternative to pig iron and scrap, ideal for producing high-quality steel.

- Induction Furnaces: Used for creating cast steel with minimal impurities.

- Alloy Manufacturing: Serves as a base for specialized steel grades and alloys.

Product Advantages

- High Purity: Minimal content of unwanted elements like sulfur and phosphorus.

- Low CO₂ Emissions: A more environmentally friendly alternative to traditional steelmaking processes.

- Consistent Quality: Uniform chemical composition ensures stable production results.

- Versatility: Perfect for steel plants focusing on energy efficiency and quality.

Why Choose Our Sponge Iron?

- Reliable Quality: Made from premium iron ore for maximum purity and stability.

- Sustainable Production: Reduction process uses natural gas or other eco-friendly technologies.

- Customized Solutions: Specifications tailored to meet customer requirements.

- Efficient Supply Chain: Global logistics solutions ensure secure and on-time delivery.

Sustainability and Innovation

Our Sponge Iron is produced in compliance with the highest environmental standards. By using natural gas as a reducing agent, we significantly lower CO₂ emissions, providing a sustainable solution for modern steel production.

Contact Us

Are you interested in Sponge Iron? Contact us for a non-binding quote or detailed information. We look forward to helping optimize your production processes.

Cold & Hot Briquetted Iron (CBI/HBI)

Learn More

Cold Briquetted Iron (CBI) and Hot Briquetted Iron (HBI) are high-density forms of direct reduced iron (Sponge Iron) specifically designed for optimized transportation and storage. The briquetting process reduces oxidation, making these products ideal for global trade and use in Electric Arc Furnaces (EAF).

Technical Specifications

- Total Fe Content: ≥ 90%

- Density:

- CBI: 4.5 – 5.0 g/cm³

- HBI: 5.0 – 5.5 g/cm³

- Carbon Content: 0.1 – 0.3%

- Moisture Content: ≤ 1%

- Form:

- CBI: Cold pressed, rectangular

- HBI: Hot pressed, rectangular or cylindrical

Applications

- Electric Arc Furnaces (EAF): Ideal raw material for steel production with reduced energy loss.

- Induction Furnaces: High-quality alternative to scrap for consistent steel quality.

- Export Markets: HBI’s high stability makes it perfect for international trade.

Product Advantages

- Oxidation Resistance: High density prevents corrosion during transport and storage.

- Transport-Friendly: Easy to handle, store, and cost-efficient to ship.

- High Purity: Consistent quality with minimal impurities.

- Global Acceptance: HBI meets international standards and is suitable for all steel mills.

CBI vs. HBI – The Difference

- CBI (Cold Briquetted Iron):

- Made by cold pressing Sponge Iron.

- Suitable for shorter transport routes or direct processing.

- HBI (Hot Briquetted Iron):

- Made by hot pressing at temperatures above 650°C.

- Offers higher stability and strength, ideal for storage and export.

Why Choose Our CBI/HBI?

- Safety and Stability: High density minimizes fire and oxidation risks.

- Sustainable Production: Reduced using eco-friendly technologies.

- Flexibility: Specifications tailored to customer requirements.

- Reliable Delivery: Worldwide distribution with efficient logistics solutions.

Sustainability and Efficiency

CBI and HBI are not only produced using environmentally friendly methods but also offer an efficient alternative to traditional pig iron or scrap, significantly reducing CO₂ emissions in steel production.

Contact Us

Interested in CBI or HBI? Consult with our experts and receive a customized quote tailored to your requirements.

Manganese Ore – Essential Raw Material for the Steel and Alloy Industry

Learn More

Manganese ore is indispensable in steel production, enhancing the hardness, strength, and wear resistance of steel. It is also a key raw material for producing ferroalloys such as silico-manganese and ferro-manganese, which are widely used in the steel and foundry industries.

Technical Specifications

- Mn Content: ≥ 40%

- SiO₂ Content: ≤ 5%

- Fe Content: ≤ 12%

- Impurities: Low sulfur and phosphorus content

- Form: Lumps or fine grains

Applications

- Steel Mills: Enhances steel quality through desulfurization and decarbonization.

- Ferroalloys: Base material for silico-manganese and ferro-manganese used in the production of construction steel, stainless steel, and heat-resistant alloys.

- Chemical Industry: Utilized in batteries and as an oxidizing agent.

Product Advantages

- High Purity: Reduced levels of undesirable elements.

- Versatility: Wide range of applications in the steel and chemical industries.

- Reliable Quality: Consistent composition for optimal production processes.

Why Choose Our Manganese Ore?

- Premium Quality: High Mn content ensures maximum efficiency.

- Sustainable Extraction: Eco-friendly mining and processing techniques.

- Reliable Supply: Global logistics solutions for timely deliveries.

- Flexibility: Chemical specifications tailored to your requirements.

Contact Us

Would you like to learn more about our manganese ore? Contact our team for detailed information or a customized quote.

Chromite and Chromite Concentrate – Premium Quality for the Steel and Refractory Industry

Learn More

Chromite is an essential raw material for producing stainless steel, heat-resistant alloys, and refractory materials. Our chromite and chromite concentrate are sourced under stringent quality controls, offering high purity to meet the demands of modern industries.

Technical Specifications

- Cr₂O₃ Content: ≥ 45%

- FeO Content: ≤ 15%

- SiO₂ Content: ≤ 5%

- Impurities: Low sulfur and phosphorus content

- Particle Size: Fine or lumpy, based on requirements

Applications

- Steel Industry: Production of stainless steel and specialty alloys.

- Refractory Industry: Manufacturing refractory bricks, crucibles, and linings.

- Chemical Industry: Chromium compounds for electroplating and pigment production.

Product Advantages

- High-Purity Raw Material: High Cr₂O₃ content for maximum production efficiency.

- Wide Application Range: Suitable for steel production and chemical processing.

- Consistent Quality: Stable chemical and physical properties.

Why Choose Our Chromite?

- Superior Purity: Minimal impurities for optimal performance.

- Tailored Solutions: Flexibility in particle size and composition.

- Reliable Supply Chain: Worldwide delivery with guaranteed punctuality.

- Sustainability: Mining and processing follow the highest environmental standards.

Contact Us

Looking for high-quality chromite or chromite concentrate? We offer solutions perfectly tailored to your requirements. Contact us today for a customized quote.

Industries – Steel and Aluminum for Automotive, Mechanical Engineering, Construction & more

Steeligent offers tailored solutions made of steel and aluminum for various industries. From the automotive industry to the energy sector, we support your projects with high-quality materials.

Branchen, die wir beliefern

Automotive Industry

Learn more

Lightweight yet strong: Our materials ensure durable and safe vehicle components.

Body construction: Our steel and aluminum solutions are widely used in vehicle body manufacturing.

Chassis components: We supply high-quality materials for chassis components such as axles and springs.

Drivetrains: Our precision materials are used in transmissions and engines.

Steel for the Automotive Industry – Tailored Solutions with EU Standards

The automotive industry demands materials of the highest quality and precision. At Steeligent, we provide certified steel and aluminum products specifically designed to meet the needs of this sector, all in compliance with strict European standards.

Our Offerings for the Automotive Industry:

- Vehicle Frames (Chassis)

- Interior Frames and Reinforcements

- Body Panels

Why Choose Steeligent?

- Highest Quality: Our materials meet all relevant EU standards.

- Wide Selection: High-strength steel and aluminum solutions for every automotive application.

- Personalized Support: Our experts help you choose the optimal material for your project.

- Flexibility: Solutions for mass production, prototypes, or custom requirements.

Mechanical Engineering

Learn more

Precision and durability: Steel and aluminum for high-performance machines and systems.

Aerospace

Learn more

Innovative materials for maximum lightness and durability in aerospace.

Construction Industry

Learn more

Hochfester Stahl und Aluminium für nachhaltige und robuste Bauprojekte.

Shipbuilding

Learn more

Corrosion-resistant materials for ships and offshore structures.

Energy Industry

Learn more

Specialized solutions for wind power, solar systems, and other sustainable energy technologies.

Electrical Engineering and Electronics

Learn more

Steel and aluminum for precision parts and durable electronic components.

Food Industry

Learn more

Stainless steel for hygienic and low-maintenance solutions in sensitive production areas.

Transportation and Logistics

Learn more

Reliable solutions for robust transport and storage solutions.

Contact Us

Do you have any questions or would you like to place an order? Our team is happy to assist you.

Inquiry form